The challenge has been well known for a decade: Service providers are investing billions of dollars into infrastructure, but the resulting networks are complex and expensive to operate. To make matters more difficult, service provider business models are changing. Traffic is increasing rapidly over their more complex and powerful networks, but revenue remains relatively flat and untenable in the long run.

There is also a major transition in the services offered over these networks, from long-term circuit-based services with predictable bandwidth, to mostly best-effort, on-demand, interactive data services with rich quality-of-experience requirements.

Service providers have identified a number of shortcomings that make it difficult to respond to these evolving service requirements. They include:

- Rigid network structures that are not suitable for the unpredictable, fluctuating, and increasing traffic load.

- Long-term, static service provisioning that cannot rapidly meet agile on-demand customer requirements.

- Layers of special purpose equipment, which result in complicated and inefficient provisioning and management.

These network issues are being addressed by a number of industry organizations. For example, service providers have banded together to develop network functions virtualization (NFV) standards under the auspices of ETSI to better define problems and propose long-term solutions. The Open Networking Foundation (ONF) is another group with similar objectives. They are creating software-defined network (SDN) specifications based on the OpenFlow protocol that abstract control from multiple layers and, in effect, collapse layers through software control.

As a result of these and other efforts, carriers and content providers are advocating a new paradigm for intelligent networks that collapses network layers and improves network efficiency.

The path toward convergence

The new paradigm’s advanced capabilities will be realized through:

- virtualization

- software programmability

- layer convergence in network equipment

- application awareness.

The NFV and SDN initiatives address the operational expense incurred by traditional large networks consisting of back-to-back devices, often in the same site, each with its own control plane and management software. Today, creation of an end-to-end service may require configuration of separate devices for Layer 3 routing, Layer 2 Ethernet, and Layer 1 optical. Configuration of, for example, BGP and IGRP at Layer 3, Carrier Ethernet bandwidth profiles, OAM and quality of service (QoS) at Layer 2, and Optical Transport Network (OTN) at Layer 1 — all using IPv4 and IPv6 — requires significant equipment, labor, and expense.

Meanwhile, service provisioning and delivery requirements have evolved. In the past, it might take 60 days to create a new service; now customers want it in 60 seconds. In addition, customers may change day-to-day requirements for more, less, or different services and they are willing to pay for this flexibility.

The solution is to build a network that is intelligent enough to make decisions about different layers using instantaneous traffic awareness and deliver SLA-compliant services based on traffic management, QoS, and security implementations from a single hardware and software platform. To support this requirement, collapsing some OSI layers into a single, more intelligent device should provide greater control, more efficient network design, faster service provisioning, and lower operational expenses.

The question is, what will converged equipment, a converged network, or converged management look like?

The look of the future

The investment in existing protocols – e.g., OTN, IP, IGP, BGP, EGP, MPLS, VPLS, MPLS-TP, VRF, PBB, PBB-TE, Carrier Ethernet 2.0. plus vendor proprietary protocols – is significant, and these protocols are difficult to orchestrate into a simple management system. Coordinating them across multiple autonomous networks will be an even larger challenge. Nevertheless, the diagram below shows how today’s Layer 1-3 protocols map into a new converged network.

|

| Figure 1. The transition from today’s infrastructure to a converged network. |

Proactive companies are adopting industry standards to enable layer convergence. We see this integration with the morphing of Layer 1 optical functions like mux/demux into switch routers, and conversely we see switching blades added to formerly pure WDM transport systems. Using low-latency optical/electrical/optical functions like cut-through switching and sophisticated packet processing that gives priority to individual flows will enable the efficient grooming of packets for transmission over wavelengths and preserve the low-latency characteristics of WDM transport. OTN may play a critical role in switch router equipment that integrates ROADM, forward-error correction (FEC), OTN, and other formerly optical transport characteristics.

The implementation of other protocols in these converged devices will further enhance the simple orchestration and control of dynamic, flexible new services. The IETF standard for path computation elements (PCEs) can play a role in provisioning and route restoration. Another IETF standard, ALTO, could serve as a resource mapping service for layer coordination. OpenFlow has a similar mission of creating an abstraction layer that enables graceful orchestration of heterogeneous network equipment.

Additional efforts are needed

These efforts, while impressive, are a long way from being the comprehensive solutions that the industry needs, however. To create a converged network, these protocols must encompass a vast number of functions and applications that include:

- Performance optimization of network stacks on virtualized systems

- Verification of unknown code running on shared platforms

- Extensible software stacks for implementation of new functions

- Mechanisms for migration of stateful devices

- Resource allocation mechanisms for shared/virtualized platforms

- Integrating new software into legacy networks

- Management abstractions and policy language frameworks

- Measurement of service performance in service provider networks

- Security, performance, and monitoring applications

- Challenges for policy verification of new service and devices.

New protocols and hypervisors with APIs, TLVs (type-length values), MIBS (management information bases), and new data models will be needed to create the basic tools to implement these functions. Standards organizations like the OIF, ONF, IETF, IEEE, ITU-T, and others will each provide pieces of the solution. Optical vendors will implement more software with these protocols along with proprietary functions for their transport platforms to create the foundation for new flexible services and more efficient modes of operation.

Converged networks will have awareness of the underlying traffic patterns and content to help optimize performance and insure QoS. One approach to this goal is s-Flow (see below), a protocol that samples flow data and analyzes content to help optimize network resources.

|

Figure 2. Protocols such as s-Flow likely will be needed to supplement the specifications

from organizations such as the NFV and ONF. |

Networks will need to be aware of thousands of services in parallel, requiring efficient packet processing and hashing algorithms. Dedicated deep packet inspection (DPI) and analytics engines will become the distributed policy enforcement mechanisms of these new converged networks.

In the optical realm, auto-power balancing and BER will be routinely tracked for all links and transceiver pairs. These mechanisms will become part of a real-time, distributed, dynamic network capable of changing rapidly even as they support hundreds of thousands of flows.

These developments in network convergence promise significant long-term operational efficiencies for service providers. In the closed confines of the modern data center, we have seen some promising trends in convergence. Migrating these operational advantages to the wider service provider community will happen over the coming years as standards develop and newer devices with more powerful processing, open APIs, and integrated switching/routing/optical transport hardware come to market.

Due to the number and complexity of the protocols involved in wide area networking, a standards-based, evolutionary approach is preferable over a radical telecommunication overhaul from both a cost and performance perspective. Industry support for these new approaches to converged networks will create dynamic, fluid, and operationally efficient service provider operations.

Mannix O’Connor is director of technical marketing for MRV Communications. He can be reached atmoconnor@mrv.com

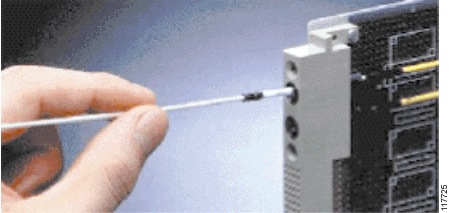

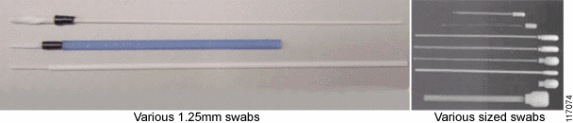

Caution: Wet cleaning is not recommended for bulkheads and receptacles. Damage to equipment can occur.

Caution: Wet cleaning is not recommended for bulkheads and receptacles. Damage to equipment can occur.

Warning: Invisible laser radiation might be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments.

Warning: Invisible laser radiation might be emitted from disconnected fibers or connectors. Do not stare into beams or view directly with optical instruments.